What is Reinforced Autoclaved Aerated Concrete (RAAC)?

What is Reinforced Autoclaved Aerated Concrete (RAAC), why is it such a problem now and do I need a RAAC Survey?

To understand the recently reported problems with RAAC we should first drop the R for Reinforced bit. Autoclaved Aerated Concrete (AAC) has been a popular construction material in the UK for decades, lauded for its lightweight properties and energy efficiency.

However, recent concerns have emerged about Reinforced AAC’s structural integrity over time. The addition of steel reinforcement to create RAAC panels can lead to deterioration of the material, leading to the need for comprehensive surveys to assess its condition.

Understanding RAAC

Reinforced Autoclaved Aerated Concrete (RAAC), is a type of precast concrete known for its excellent thermal insulation, fire resistance, and lightweight nature.

It was a popular choice for both residential, commercial and public buildings from the mid-1950s to the mid-1980s. It was a light weight, low cost alternative to traditional concrete with good fire resistance properties.

However, the issue that has recently been reported in the UK relates to the reinforcement within RAAC. It has been known for several years that RAAC is not as robust as traditional concrete.

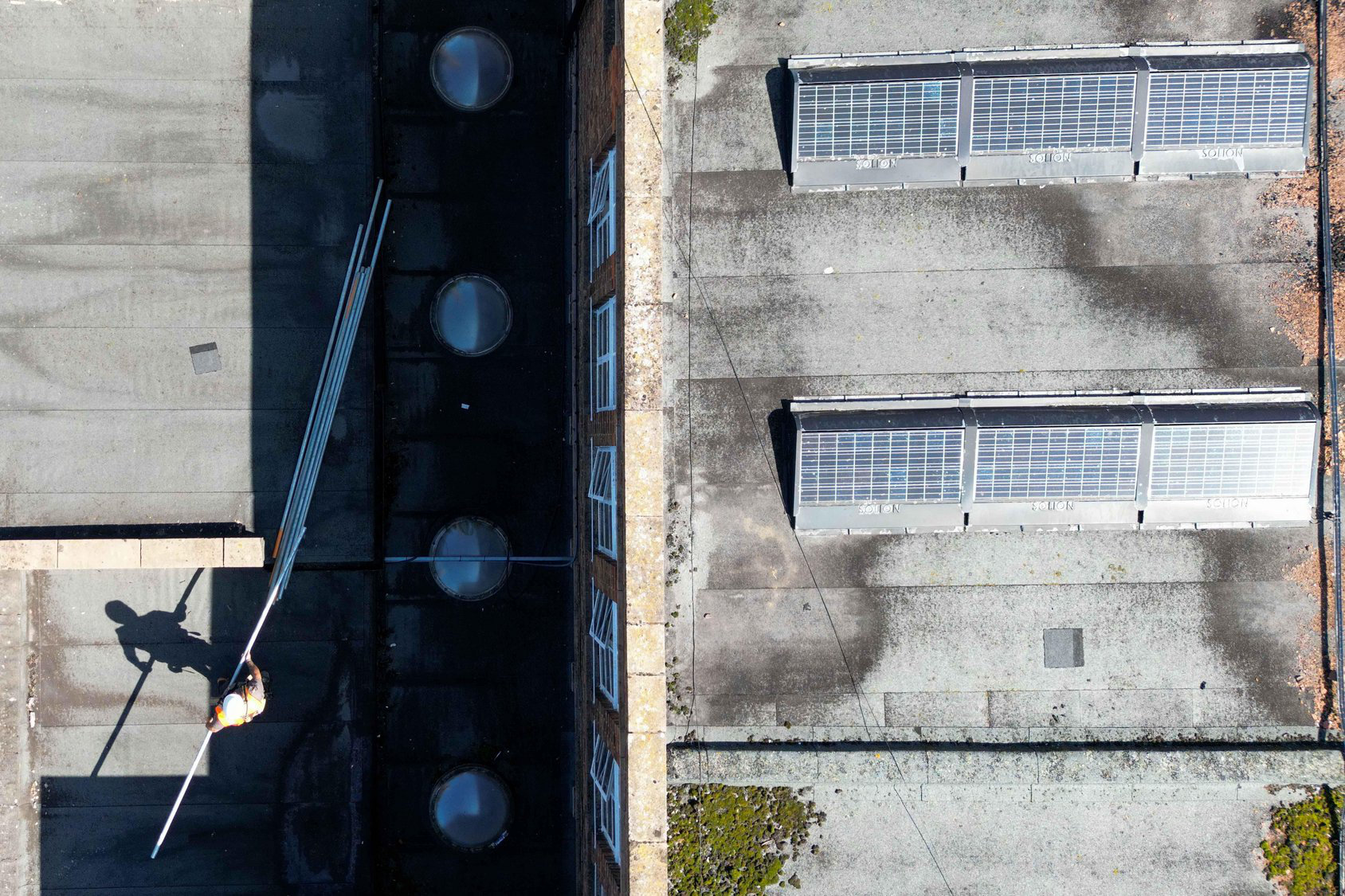

RAAC is prone to deflection, cracking and other related problems. Due to its porous nature the reinforced steel contained in RAAC is vulnerable to corrosion, which will exhibit in signs of deterioration over time, compromising structural stability.

LGA calls for RAAC Surveys

This problem is deemed sufficiently serious to have warranted the Local Government Association advising its members to check as a matter of urgency whether any buildings in their estates have roofs, floors, cladding or walls made of RAAC.

However, RAAC was not just used in schools and healthcare facilities. It was also used in the construction of both low-rise local authority and private sector housing and in commercial buildings.

What causes RAAC to deteriorate?

RAAC deterioration can result from various factors, including:

Moisture Infiltration

Over time, moisture can penetrate the concrete, leading to internal corrosion of the steel reinforcement, commonly known as ‘concrete cancer.’

Poor Workmanship

Inadequate construction practices or poor workmanship during the installation of RAAC can increase the likelihood of structural issues.

Many instances have been found where refurbishment work has led to builders drilling into RAAC panels substantially degrading its structural integrity and exacerbating issues with moisture ingress.

Age and Exposure

Older RAAC buildings may be more prone to deterioration, especially if they have been exposed to harsh environmental conditions.

Why RAAC Surveys are Essential

The structural integrity of RAAC buildings is a critical concern for property owners and developers. Ignoring potential issues can lead to safety hazards requiring costly and extensive repairs

In addition to ensuring any RAAC is being correct maintained, owners of buildings of this type of construction should check as a matter of urgency whether they hold building or other insurance that will respond to claims for rectifying or mitigating issues with RAAC.

There is a distinct possibility that insurers may seek to exclude future claims arising from the presence of RAAC. While a building owner’s current building insurance might include cover for RAAC claims, when that policy comes to an end and or is renewed, insurers may seek to exclude RAAC cover. It is in the interest of building owners’ to proactively identify RAAC and notify insurers accordingly.

Our expert team can help with surveys to identify RAAC, assess its conditions, advise on any mitigation to prevent further deterioration, and provision of a report to support any insurance claim.

RAAC Expertise

We have a team of experienced chartered surveyors with the specialism to undertake RAAC surveys and assessment.

Our experts are equipped with the knowledge and tools to evaluate the condition of RAAC structures accurately.

Comprehensive RAAC Assessments

We conduct thorough surveys, including visual inspections, non-destructive testing, and moisture analysis, to identify any issues within buildings containing RAAC.

RAAC Risk Mitigation

Identifying potential structural problems early can help you take proactive measures to mitigate risks, such as reinforcing or repairing the RAAC elements before they deteriorate.

Cost Savings

Addressing RAAC issues promptly can save you significant repair costs in the long run, ensuring your property is safe and protecting your investment.

Tailored Solutions

We provide customized solutions based on the specific needs of your property, whether it’s a residential, commercial, or industrial structure.

Conclusion

Reinforced Autoclaved Aerated Concrete structures have long been a staple in the UK’s construction landscape.

However, concerns surrounding their structural integrity necessitate proactive measures.

We offer comprehensive RAAC surveys and reports to help property owners and developers identify and address potential issues promptly.

Contact

For more information on RAAC or to commission a RAAC survey call us on 01603 577 362. To request a call back from a member of the team, please fill in our Contact Us form.

For advice on Reinforced Autoclaved Aerated Concrete (RAAC) direct from one of our surveyors, please call our RAAC specialists on 01603 577 362.

If you would like us to call you, please fill in our Contact Us form and we will call you back.

Link: Contact Us

Team members shown:

- Henry Woodley

- Will Mantell-Sayer